At Comaxel we always have an open discussion with our clients about quality level of the components, which process is expected and other relevant details. Based on this we can recommend the full tooling package.

Our plug range goes from one-off based on MDF finished with high quality topcoats till high end master blade plugs. General tolerances are +-1mm and vacuum integrity with drop of maximum 20mbar/20 minutes at 3% residual pressure.

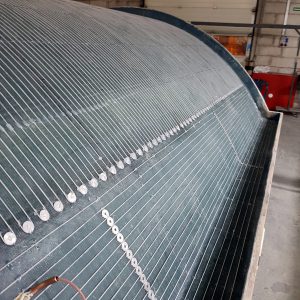

At Comaxel we provide our clients a wide range of specialized moulds. Every mould is produced with focus on quality to ensure our clients ongoing production of high-end components.

Through dialog we can recommend what type of mould will give the best results dependant on our client’s choice of production process and demands in surface finish.

Our range of moulds starts with standard vinylester based unheated moulds till high end epoxy moulds with hydraulics and built in electrical microprocessor-controlled heating system.