Our products and services

Plugs and moulds

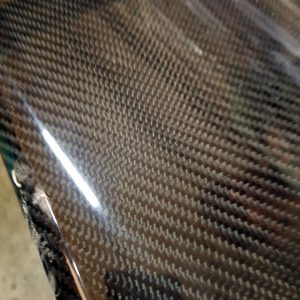

Composite parts

Mega structures

Recycling – Go Green

Composite sheets

Comaxel: Who We Are

Comaxel Spółka z ograniczona odpowiedzialnością was established 2013 in Goldap, Warmian Masurian. Located in the most beautiful area of Poland surrounded by lakes and forests.

Facilities:

At present, our team comprises nearly 100 dedicated individuals, collectively striving to deliver premium-quality products to our esteemed clients across Europe. Housed within our expansive 5000m2 production facilities, equipped with state-of-the-art 10mt traverse cranes, we ensure efficient and precise manufacturing processes. Our new head quarter warmly welcomes our guests and our new production facility is equipped presses, large scale beam saw, CNC machinery for kitting and milling robot making Comaxel able to handle any request of modelling and mould production.

Products:

Our product portfolio predominantly revolves around utilizing epoxy, glass, and carbon fibers, constituting approximately 99% of our supply materials. We boast a diverse range of offerings, catering to every conceivable demand of our clientele. From the fabrication of intricate glass fiber washers to the monumental achievement of producing 35m Flettner rotors – the largest ever manufactured globally – we continually push the boundaries of innovation and excellence. Highest quality CSC approved composite sea containers approved for pay load above 28 ton. Advanced epoxy/carbon booms for sailing yachts. High end Composite wing sails up to 40m in height. Advanced composite climate solution regulating water flow during flooding. Carbon part production for a broad spectrum of clients.

Proto typing and development:

Central to our ethos is the unwavering commitment to shepherd an idea from conception to fruition. With an extensive wealth of expertise in prototyping, we offer comprehensive services encompassing design, engineering, plug and mould creation, prototype development, in-process testing, and production setup.

Documentation:

Ensuring transparency and accountability, we meticulously document every facet of our production process. Each component manufactured by Comaxel comes with complete documentation, securely stored on our Client Shared Servers (CSS) as part of our robust Project Management Program.

Leadership:

Beyond our dedication to craftsmanship, we are deeply invested in fostering a culture of environmental stewardship and safety consciousness. With utmost reverence for our natural surroundings, we prioritize sustainable production practices and prioritize the safety and well-being of our workforce. One result is that we reduce our carbon footprint by thousands of tons per year, only using sustainable power based on wind, solar and water for our production. Comaxel takes pride in its adherence to industry-leading standards, holding certifications across the board, including ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018.

Pedigree:

Furthermore, we are privileged to collaborate with esteemed partners hailing from Finland, Sweden, Norway, Denmark, Switzerland, Austria, Italy, Germany, France, Lithuania and Poland, fostering mutually beneficial relationships that underscore our global reach and influence.

For more info please check – COMAXEL Flyer 2025

Project under the 15th competition of the EUROSTARS-2 program.

Our Team at Comaxel

FOUNDERS

Michael Rann

Co-Founder, CEO

ADMINISTRATION

Ewelina Brodowska

Accounting

Beata Jaworowska

Supply Specialist

ENGINEERS

Jakob Lorentsen

Engineer

Karol Budrowski

Engineer

PRODUCTION

Sebastian Murawski

SFM

Agnieszka Minksztyn

Document Coordinator

Our benefits

Vision

Mission

First approach

At Comaxel we approach all new development work and projects with full commitment.

So if we are able to help you with a new idea or you are looking for a producer of your composite parts please feel free to approach us any time.